Businesses thrive on packaging that gets to the customers in a safe, effective way. The problem, however, is that they might think that there’s enough protection, only for it to break during transit. That’s never fun.

The simplest solution that you get is having better packaging. That’s right, it’s a simple series of steps, but the overall benefits that come with these packaging adjustments can be felt, reverberations that many customers resonate with.

The Materials and Insides Matter

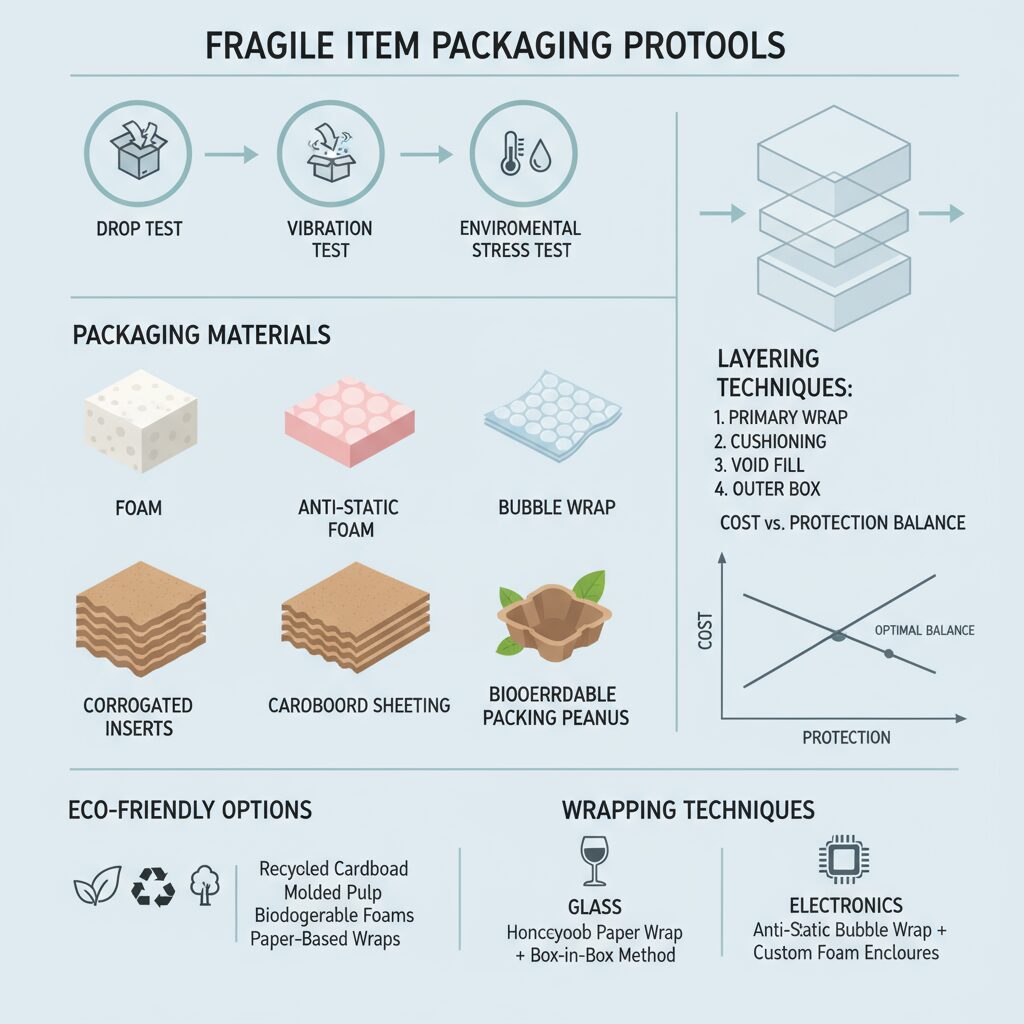

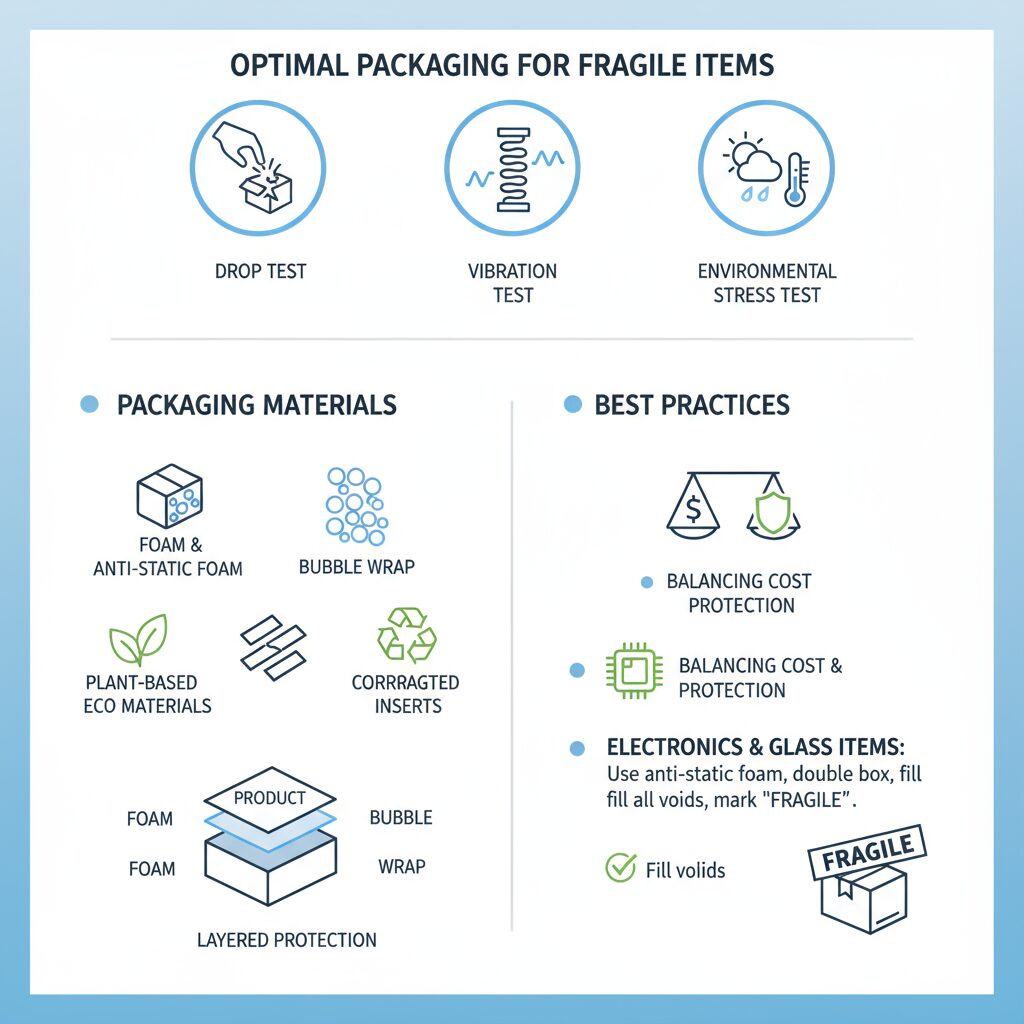

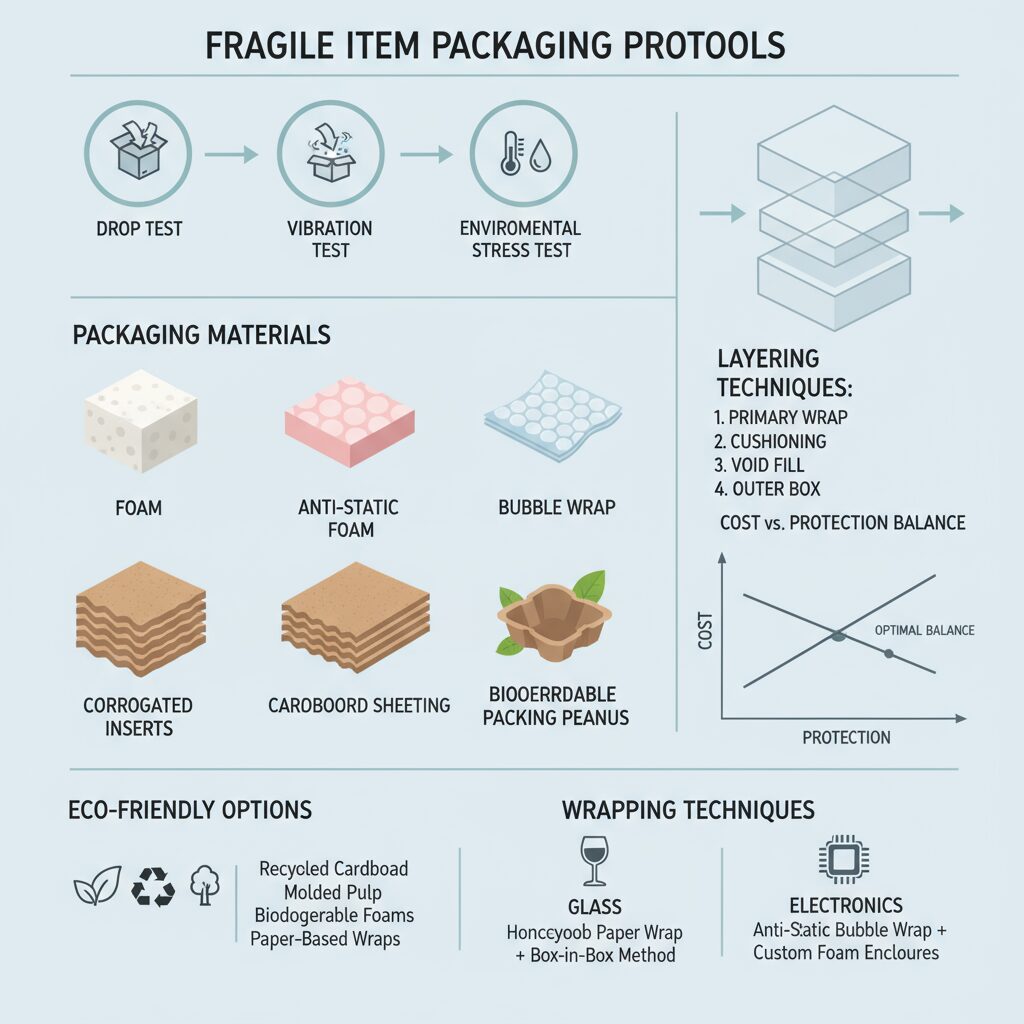

Your first solution is to look at the materials that you use both outside and inside.

If you need extra protections, a corrugated box might be the solution you’re looking for. Though they tend to cost more, they offer worthwhile benefits that you’ll be grateful to have when shipping out.

But, the insides matter just as much. Protecting the corners, holding the packaging in place with suspension packaging and the like are all good ideas.

If you’re looking to save money and offer protection, inserts made of cardboard might be the solution that you’re looking for. You’d be surprised at how much power protective inserts have.

Then, there’s foam. Foam is magical, and it offers limitless protection to the items that are inside. With foam, you can make it moldable too, which fits your packaging needs.

Finally, air cushions. You might want to use air cushions or pillows for your packaging needs. This will ultimately reduce your packaging, making it stronger and fit your needs.

The insides matter, just as much as the outsides.

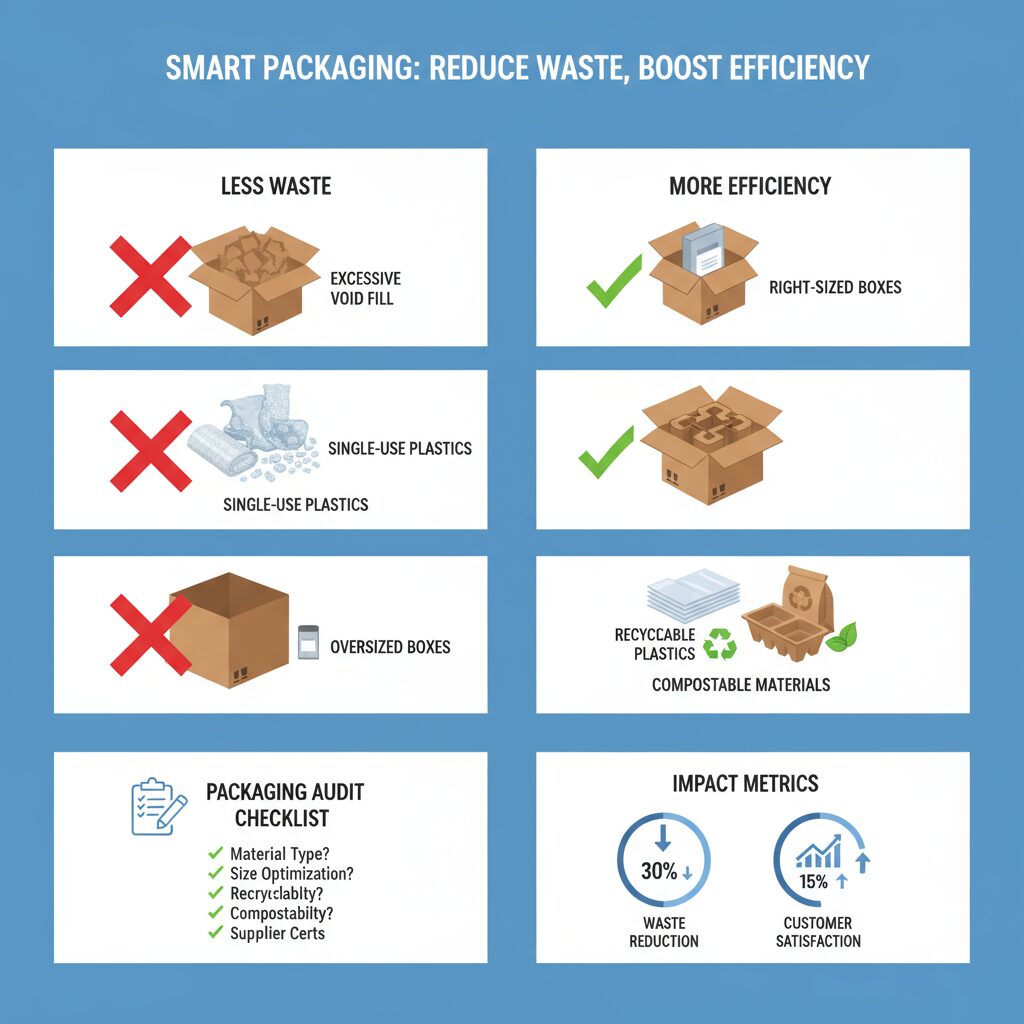

Void Fill Fittingly

The right void fill matters to a degree, but it mostly relies on how you put it in there.

Too little, and your stuff is going to break. Too much, and you can kiss your efficiency goodbye. People hate it when they get items that are just littered with void fill. Using the right amount is good.

Wrapping the void fill around the package is a good start. Try to have it sit near the center or focused in the center. If possible, keep it at least an inch away from the sides.

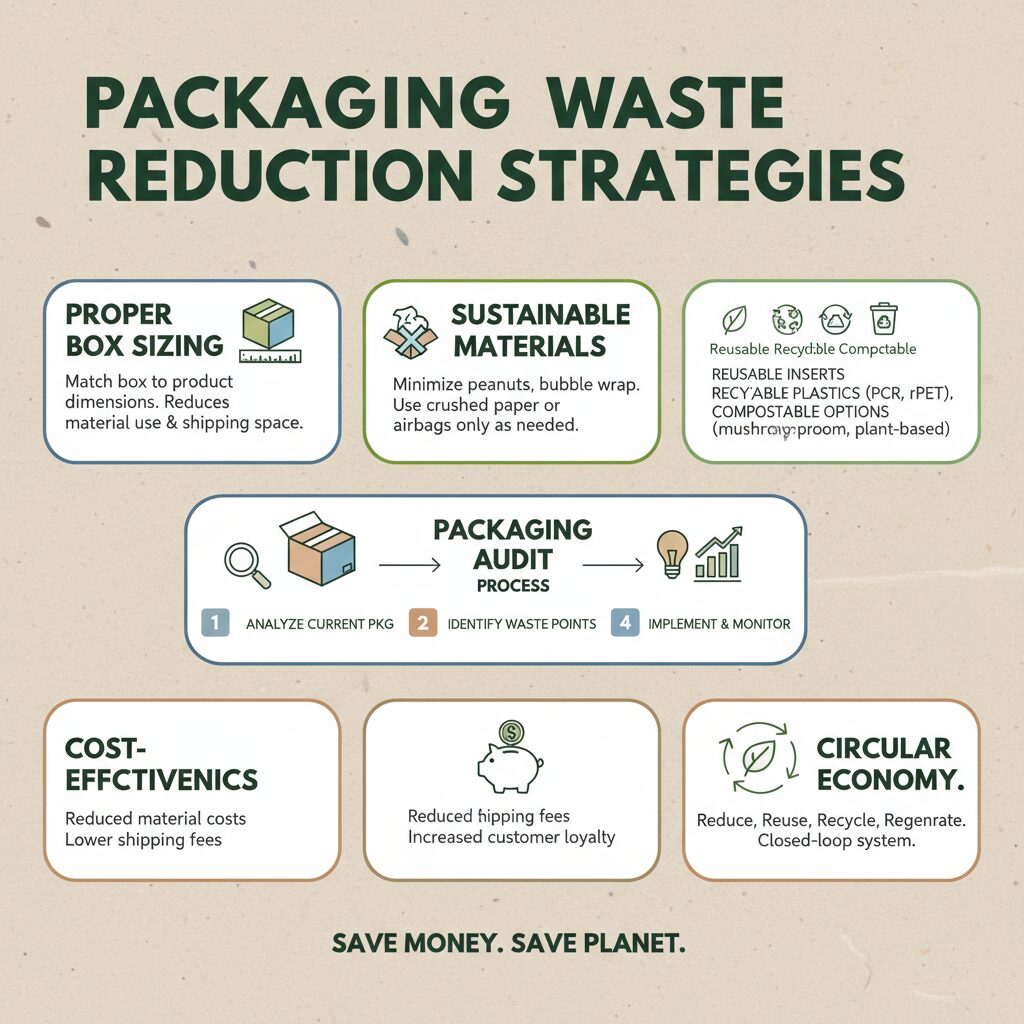

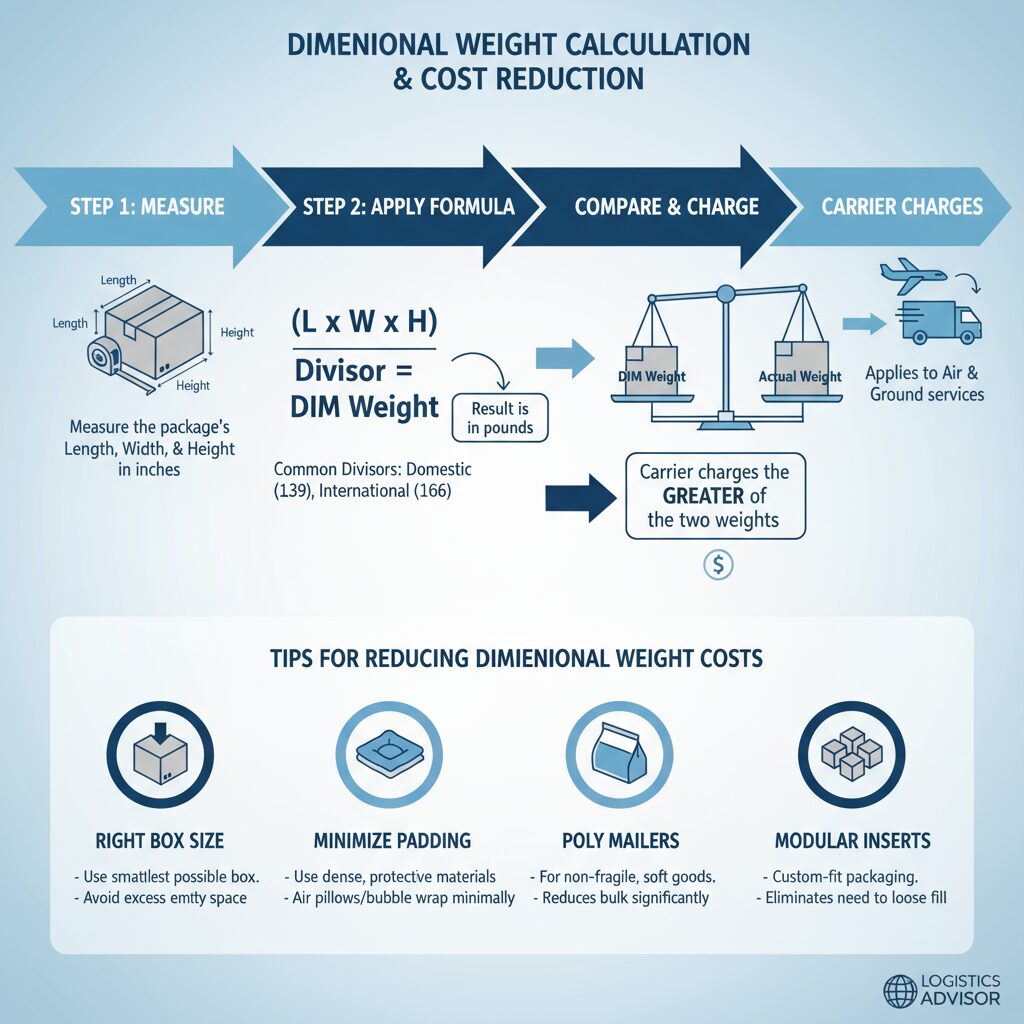

If you’re noticing you’re using too much, aim for a smaller box, as that could be the problem. It will also save you a ton on dimensional weight charges if you just have the right void fill, and the correct amounts to make it fit the needs that you have.

The Real-World Carrier Claim reduction tips

There’s a lot of carriers that don’t want you spending a ton of money on void fill or having to send out returns or refunds.

The first thing is to try to aim for almost equal weight and DIM. Don’t use oversized boxes or stuff them with foam. It doesn’t work.

When in doubt, always tell a carrier that something is fragile. You might be asked when shipping the item, but if you’re not, make sure to let them know, and also stamp on their FRAGILE HANDLE WITH CARE to help with reduction of breaks and drops.

Some shipping also helps with the efficiency and protection of these materials. Ground shipping does risk humming and static, while airplanes might be tightly cramped. Make sure to research, and choose the appropriate shipping for your needs that fits what the customers want.

Having better packaging is a simple solution to the problem of shipping damage for businesses. Being mindful of how they’re put together is not only good for your needs, but good for the overall needs that your business has, and the results these offer too.