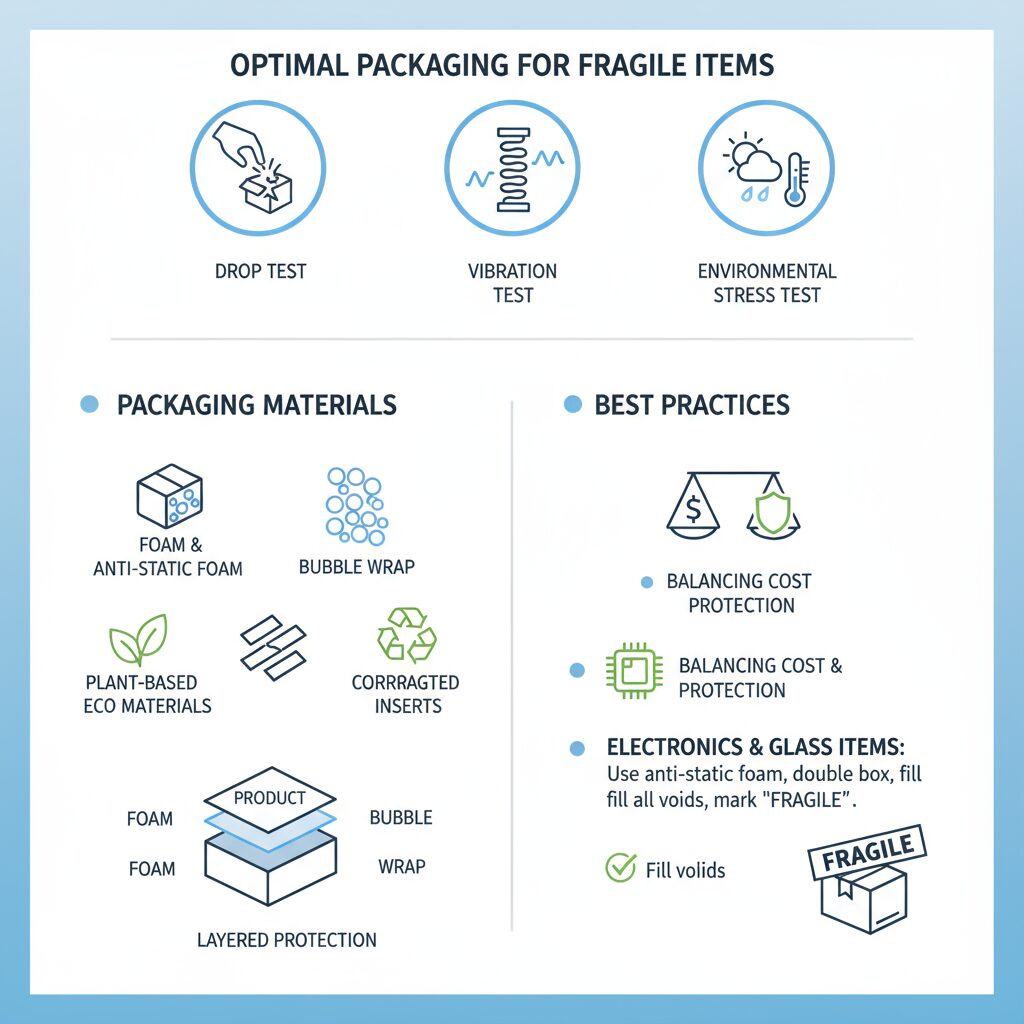

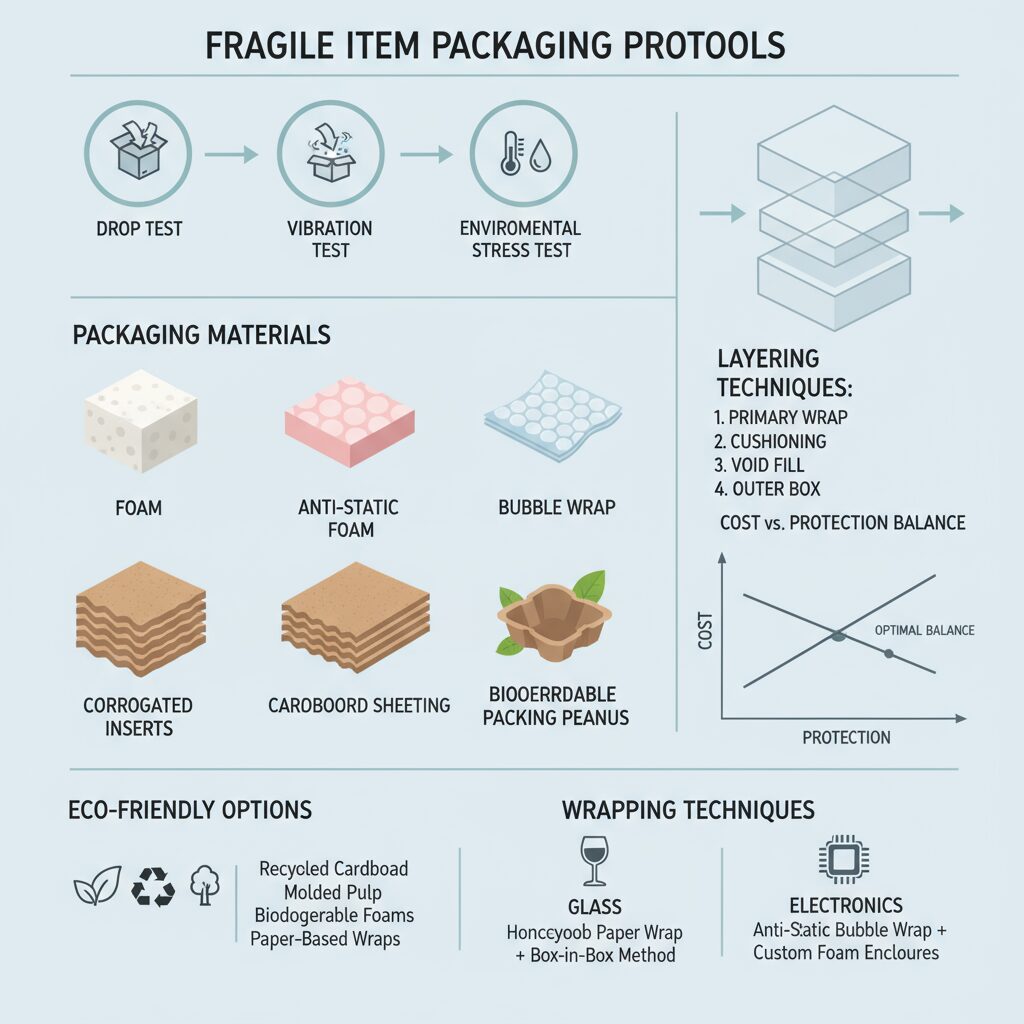

Packing fragile items is a bit of a challenge for many retailers. Which is why, in order to make sure that the items survive the transit, you want to use packaging tests to ensure that nothing is amiss.

Drop tests are one, where you drop it and see how the box is faring. If it’s able to keep its form and shape together, then it’s good. If not, it might need some changes.

Vibration tests are good too. used for electronics, this tests whether the circuits are intact after being on a humming, vibrating truck or other means of travel.

Finally, environmental stress testing such as extreme heat, cold, humidity, even rain and flood might be used. These will simulate environments where there’s extra stress involved, in order to make it easier for you to get the items together and properly protected.

Now that you know the tests, what’s the best way to protect your items so that they survive stress tests? Read on to find out.

The Effective Cushioning

A lot of cushioning is super effective for your toes.

Foam is one example, because they tend to be very strong, and you can make it modular as well.

Bubble wrap is another one, where you’re able to put it together using bubble wrapping. Though not as sustainable, there are ecofriendly options. It also tends to be the best for vibration resistance too.

With foam, you also want to choose anti-static foam, which will help reduce the static vibrations from ruining the items.

Finally, corrugated inserts. Such inserts are made with corrugated materials, and tend to be pretty strong, which are good as well for more sustainable options.

Designing for protection

You want to layer the materials in a way where there is immediate cushioning, then a good external cushion. For instance, using bubble wrap around an item directly followed by foam will help to add extra protection.

This is especially important for odd items. Adding either a corrugated or foam insert then other protections will help to ensure that the protections for those items are possible.

Balancing Costs and Protections

One thing to consider when putting together such items is using the right balancing of costs of the items and overall protections. Though it might seem okay to have these lightweight protections, it might not be enough. Too much, and you’re paying extra costs. This is why, when you’re putting together your packaging, don’t be afraid to run tests as well, which will help with seeing the true factors that are in place, and what works for you.

You want to look into plant-based ones as well, as they also double as being ecofriendly, while also safeguarding the products in place to make this even better for you too.

The Best Practices

For most of these, you want to make sure that your packaging is built around the item.

For instance, antistatic foam is one to use with this, especially for electronics. It will, in turn, make it easier for your protections to be in place. Glass is another one. Having something to wrap around this followed by an external cushion will serve to offer the best protections for your items.

When you’re building packaging for fragile items, try your best to make it so that they’re protected from all elements. Be mindful of how they’re put together, work on wrapping, and you will, as a result of all of this, build the best packaging protections that you can get, and will, as a result, craft an incredible box that will keep items protected, and customers happy.