Getting the right types of shipping supplies is important. You want something that ships the items effectively, helps with the transit, and will keep everything safe. As well, you might want something that’s more eco friendly for the items as well. This is because being ecofriendly is important, as it will help with improving the overall state of your packaging and customer perception.

You might wonder if there are good items online to buy for this. guess what? There is! Here are a few different ecofriendly packaging supplies to choose from.

Ecofriendly Products that Work

There are a few that really stand out when choosing the right supplies for ecommerce businesses.

Biodegradable mailers are one example. These are mailers that can be broken down, and usually with biodegradable mailers, they tend to be easy to toss away, because they simply break down. It’s simple, effective, and will really shake things up.

Recyclable cardboard is one example of this too. Many times, cardboard is the best material for the job, but some cardboard isn’t recyclable due to varnishes and glues. The alternative is a cardboard that you can recycle with no qualms or issues, and it works great for ecofriendly brands.

Water-based inks are a third one. These are inks that dissolve in water. With water-based inks, you’re able to have a package that’s fully sustainable, and it can be great for ecommerce brands of all kinds, especially if you want to build a product that focuses on sustainability from beginning to end.

Alternatives to Bubble Wrap

Bubble wrap is a very common one that you might want to use. But, it suffers from the problem of it being very unsustainable. It’s a plastic, so it will go and break down over time, and that’s a problem.

The solution? Bubble wrap alternatives.

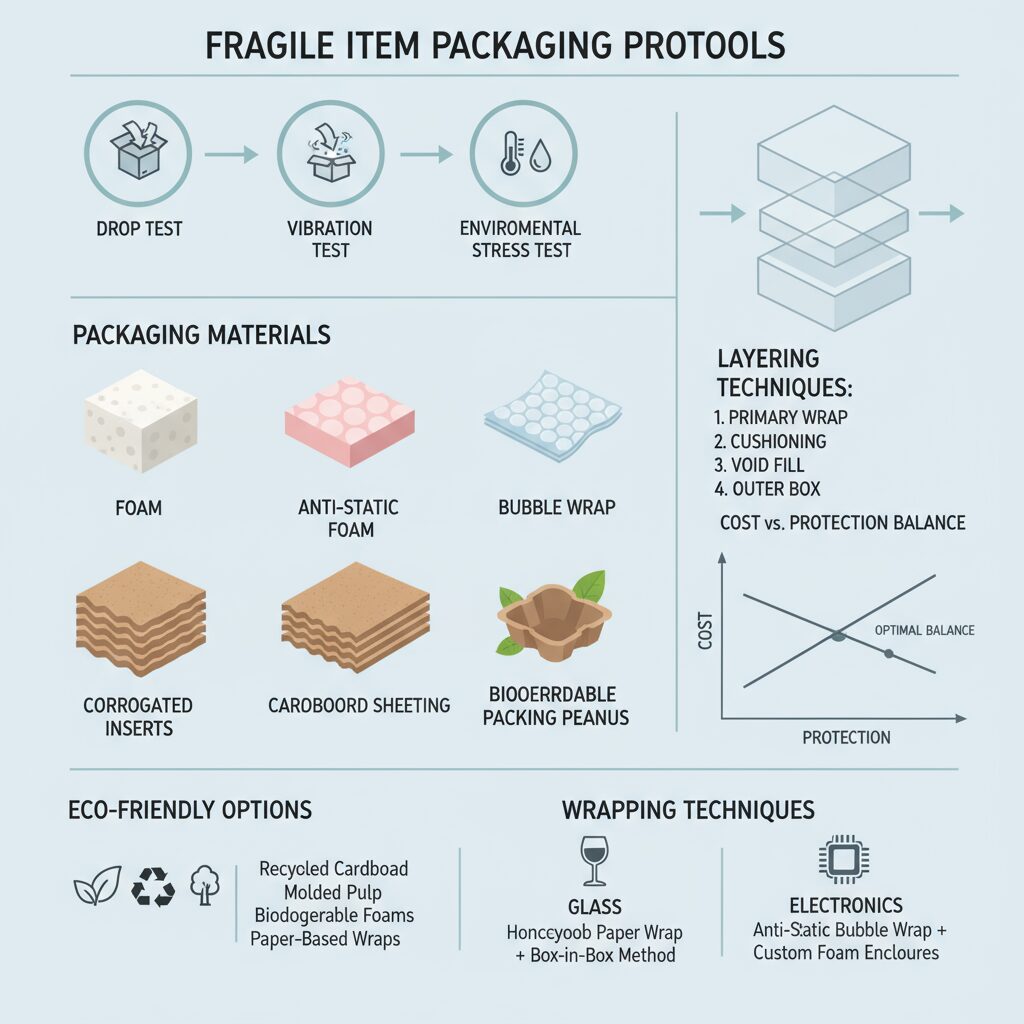

Packaging peanuts for instance are one type of way to use an alternative to bubble wrap. But polystyrene isn’t sustainable. So, the solution is to use packaging peanuts made from paper, soy, or plant-based fibers.

Mushroom packaging is another hot, new thing. It’s literally made from mushrooms, and could be a good way to use compostable alternatives to regular bubble wrap.

Some crinkle paper is another. This is also good for composting, because provided there’s no bleaches or dyes on it, it’s sustainable.

Most of the time, anything plant based that has cellulose in there is a good way to make it work, especially for corrugated and cardboard alternatives.

It can be a struggle, but there are a lot of different ways to make your ecofriendly packaging sustainable on all fronts.

More Customers Like This

Yes, customers do demand sustainable packaging, especially compared to those that are not sustainable. With more and more demand for this, it’s something that you have to consider now.

Many are focusing on the impact their packaging has on things. Plastic is overtaking our landfills, choking our oceans and reefs, and contributing to the global output of greenhouse gasses, which in turn causes problems. That’s why, it’s important for when you’re building packaging to consider those that pride on being ecofriendly. You owe it to yourself to use this, and more customers are taking charge to reduce their carbon footprint, which is why, starting now you should build a packaging experience that shines, really integrates the customer input that’s needed, and stand out amongst the sea of people that don’t have the normal packaging supplies in place.

Building the best demand possible is important, and with the right sustainable actions, you’re able to give packaging that helps make your business stand out.